Exploring Vietnam’s Leading Automatic Lathe Machining Factories

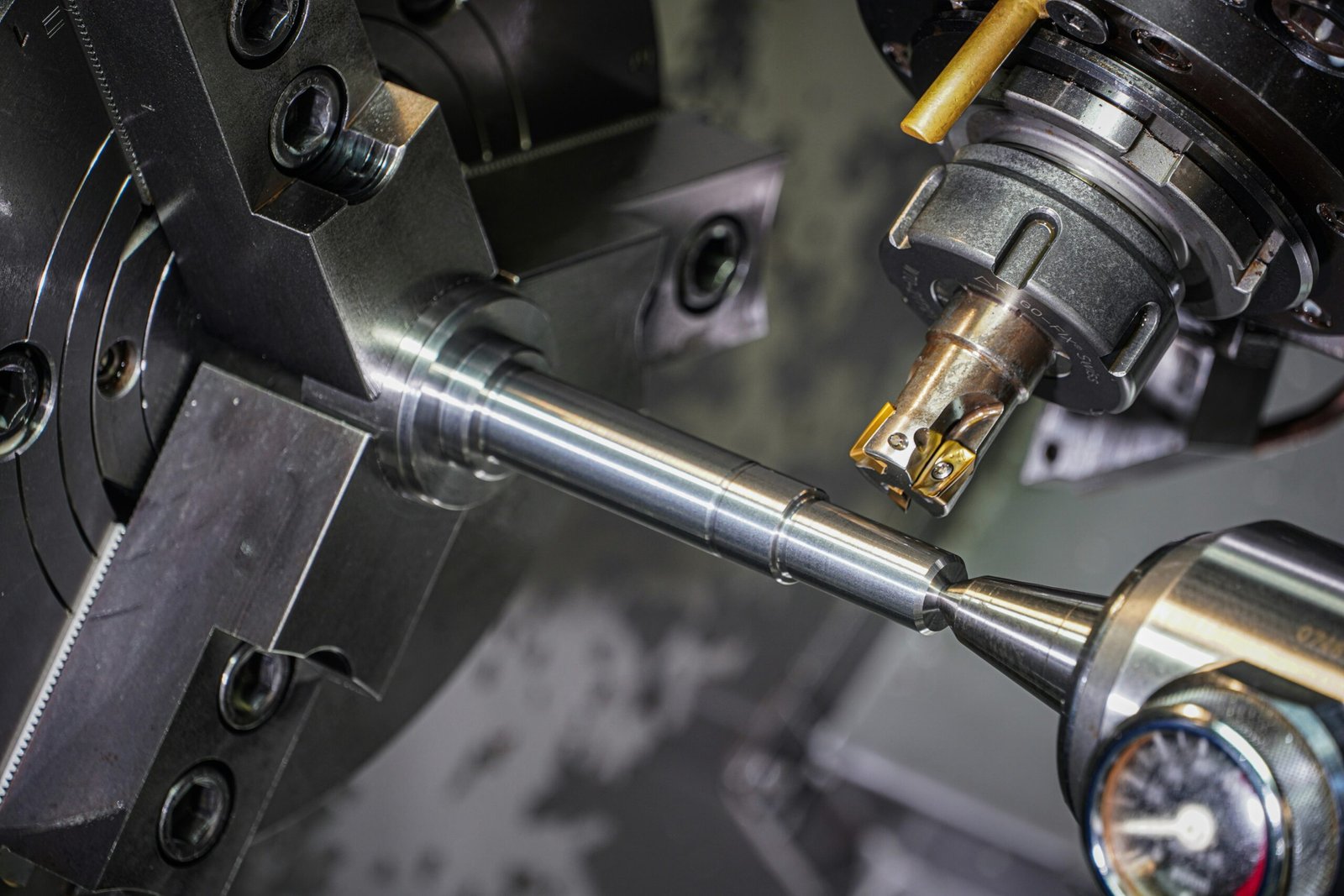

Introduction to Automatic Lathe Machining Automatic lathe machining represents a pivotal development in the realm of modern manufacturing. An automatic lathe is a type of machine tool designed to operate on its own with minimal human intervention. Originating in the early 20th century, these machines have significantly evolved, blending mechanical prowess with cutting-edge technology to...[Read More]